Tour the KWRD

Why Tour a Sanitary District?

The wastewater treatment plant is something you use every time you flush a toilet, drain a sink, or do a load of laundry.

If you’re interested in seeing how the dirty water you flushed down the drain becomes clean water in the Kishwaukee River, you can arrange a free tour of our facility at 1301 Sycamore Road in DeKalb. Tours are available for students, scouts, families, and anyone interested in how we protect the water in our community.

What You'll Learn

- How roughly 7 million gallons of wastewater a day is cleaned and purified

- The role wastewater treatment plants play in protecting public health and the environment

- Things you can do every day to protect the waters of our community and our planet

Scheduling a Tour of the District

Tours must be scheduled in advance. To schedule a tour, call (815) 758-3513. Or email us with you desired date and time, and we will call you back to confirm.

Tours are conducted between 7:30 a.m. and 3:30 p.m. Monday through Friday and take from 1 to 2 hours to complete.

Safety Guidelines

- It's important to remember this is a functioning plant. Your tour will take you in close proximity to operating machinery. For your own safety, it is important you remain near the tour guide, listen to and follow instructions, and avoid touching any equipment.

- You will encounter stairs and uneven walking surfaces on the tour.

- Closed-toe shoes are required.

- Dress for the weather, as much of the tour will take place outdoors.

Virtual Photo Tour

-

Slide title

Our tour begins at the "Headworks" building, where the preliminary treatment of wastewater occurs. During preliminary treatment, large objects and solid materials are removed from the wastewater.

Button

Slide title

Inside the Headworks, grit and solids removal takes place through the use of the Bar Screens pictured here.

Button

Slide title

After leaving Headworks, the wastewater moves into the Primary Clarifiers. These large, round tanks slow the water down, causing heavier particles to settle at the bottom while the lighter water, fats and oils rise to the top. The water is moved to the Bio-P tanks, while the solids are sent to the fermenter.

Button

Slide title

After the solids have been settled out in the primary clarifiers, the wastewater effluent is moved into the Bio-P Tanks. In the Bio-P tanks, anaerobic bacteria consume the phosphorus in the wastewater, thus removing it. In addition to effluent from the primaries, the Bio-P tank also receives effluent from the fermenter and the WAS (Waste-Activated Sludge) from the Final Clarifiers.

Button

Slide title

After moving through the Bio-P tanks, the water is pumped to our Aeration Tanks. In these tanks, wastewater is pumped with air, allowing aerobic microorganisms to break down the organic matter that was not removed at the Headworks or removed in the Bio-P tanks.

Button

Slide title

The Primary Sludge Fermenter slows and circulates the sludge that are pumped off the primary clarifiers. This process is necessary for the proper removal of phosphorus, as well as increasing the solids percentage in the sludge to ensure it can be utilized by the anaerobic digesters.

Button

Slide title

At our Operations Control building, our treatment plant operators monitor the status of our treatment system. This building also houses the blowers used to pump air into our aeration tanks.

Button

Slide title

Inside the Operations Control building, a series of blowers injects air into the aeration tanks to allow aerobic bacteria to function properly.

Button

Slide title

In our Final Clarifiers, the water is again slowed to allow solids to settle out. Liquid effluent is pumped to tertiary treatment, while RAS (Return-Activated Sludge) is cycled back into the Bio-P tanks. Any excess solids, also called WAS (Waste-Activated Sludge), are moved to the Gravity Belt Thickeners.

Button

Slide title

Tertiary treatment is the final stage for the liquid train of wastewater treatment. Here, the water moves through fine-grain sand filters that removes fine particles from the water. The water is then disinfected using UV rays, which kill any remaining bacteria and pathogens, and is finally released from out treatment plant as clean effluent.

Button

Slide title

In our anaerobic digesters, anaerobic bacteria break down organic matter in the sludge. This digestion causes the bacteria to release methane as a byproduct of their activity. The digested sludge is pumped to a storage tank, while the methane moves to our CHP generators.

Button

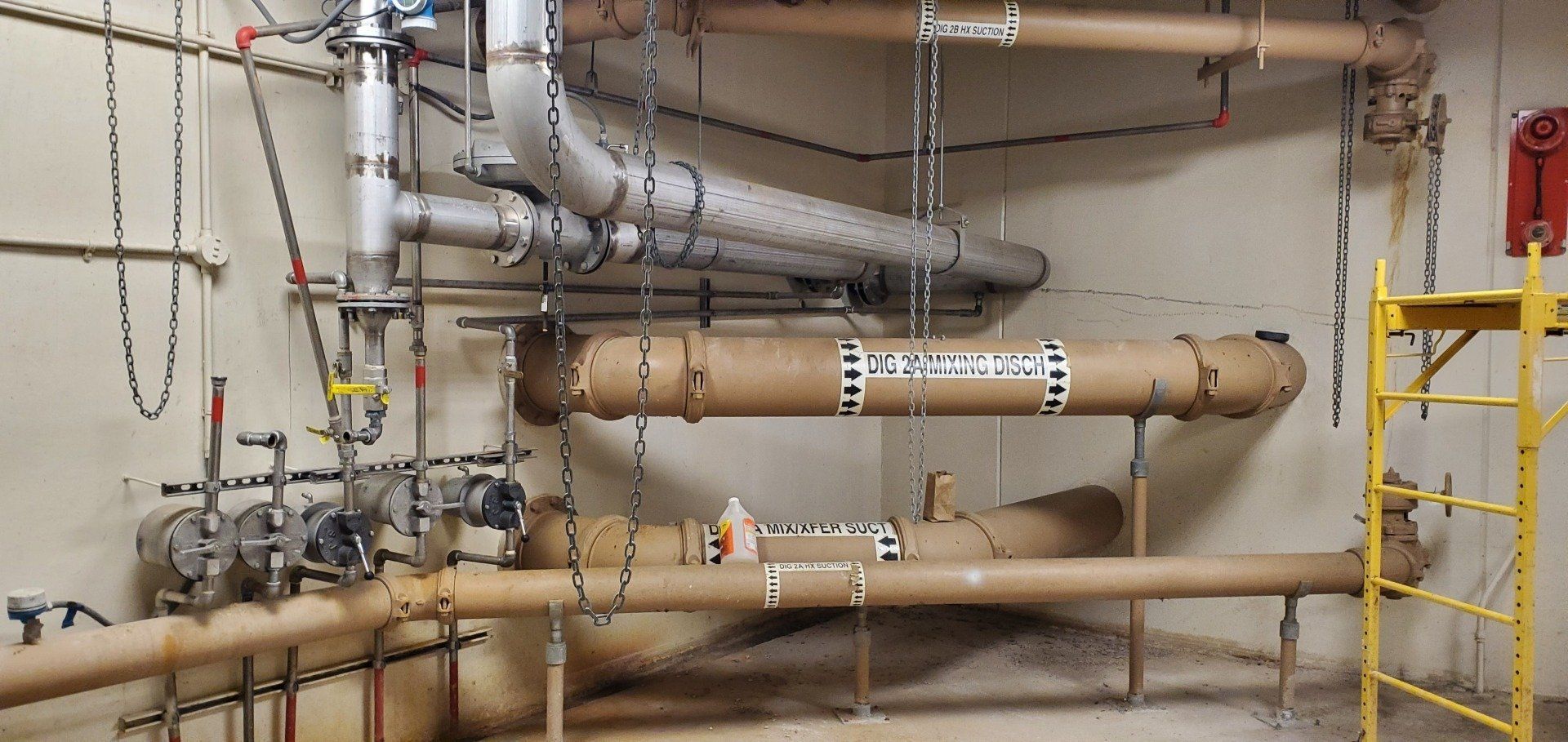

Slide title

Inside the Digester Operations Building, a criss-crossing network of pipes and pumps regulates the heating and mixing of the anaerobic digesters. The digesters must be kept within specific conditions to function properly.

Button

Slide title

After the biomass in the sludge has been processed by the bacteria in the anaerobic digesters, the resulting solids are held in this sludge storage tank. After reaching the correct solids percentage, the sludge is sent to Building 14 for dewatering.

Button

Slide title

This building, called "Building 14", houses the GBT (Gravity Belt Thickeners) and dewatering equipment. On the one hand, WAS is thickened to allow it to be processed in our digesters. On the other, sludge from the digester storage tank is dewatered and then sent to our storage facility.

Button

Slide title

Inside Building 14, the equipment shown here is used to dewater sludge from the digester storage tank. These centrifuges spin the sludge at high speeds, causing the liquid to separate from the solids.

Button

Slide title

Our Hauled Waste Receiving Station allows community members and private businesses to deposit materials such as biomass, lechate, and Fats, Oils and Grease (FOG) to help supply the digesters and CHP generator with fuel.

Button

Slide title

This Combined Heat and Power (CHP) generator converts the methane produced in the anaerobic digesters into usable electricity. This electricity is then used to power a large portion of our energy demands and provide heat for the digesters.

Button

Slide title

Our Administrative Office, located at 1301 Sycamore Road, houses our administrative employees and our testing lab. The office lobby is open to the public during work hours (7:30am - 3:30pm, Monday-Friday).

Button

Contact us

Footer form

We will get back to you as soon as possible.

Please try again later.

Kishwaukee Water Reclamation District | All Rights Reserved |

Created by Olive + Ash.

Managed by Olive Street Design.